Steel is a popular metal utilized in many industries due to its remarkable toughness, durability, and adaptability to different projects. Being aware of the many kinds of steel that are available prior to acquiring the material for any task is essential since it is available in a variety of qualities and grades.

The choice of a steel grade can be a challenge; however, it is essential to take into account the requirements of the project. The best steel firms in India can provide advice and assistance in choosing the best grade. This article offers a step-by-step guide to help you choose the right material for your needs.

Tips to choose the correct Steel grade to suit your needs:

1. Carbon Content

To get the desired properties from steel, it’s important to select a steel with the appropriate quantity of carbon. Steels with a lower carbon content are easier to shape and machine, and they can also able to be welded. However, those with higher carbon content improve the tensile strength and resistance to abrasion; however, they lose toughness.

This could result in more expensive material manufacturing costs due to lower machinability, higher temperatures of tempering, and an increased possibility of cracking at the quench. While other alloying elements aid in enhancing strength and toughness however their effects are less important than carbon, and it varies based on the particular element that is that is used.

2. Operating Environment

The working environment is crucial when choosing the right steel grade. The conditions under which the steel is placed are operating and have an impact on the quality of its performance. Physical factors like frequencies, pH levels, and temperature affect the steel’s operational conditions.

For example, in warehouses for industrial use in which large machines are utilized in the warehouse, high temperatures are frequently produced, which could alter the steel’s performance as time passes. In the same way, MS chequered plates can be affected by high temperatures generated from furnaces or other instruments. Therefore, selecting the correct steel grade according to the environment in which it will be used is crucial.

3. Strength

When choosing a steel material when choosing material, it is essential to take into account the strength of the material, which is the capacity to withstand stress or tension. To determine the strength of the steel, take a small sample of the steel in an equipment and slowly apply force externally to the item while measuring its endurance by using an extensometer. Tensile strength is measured by the pressure that the steel can withstand before breaking.

4. Machinability

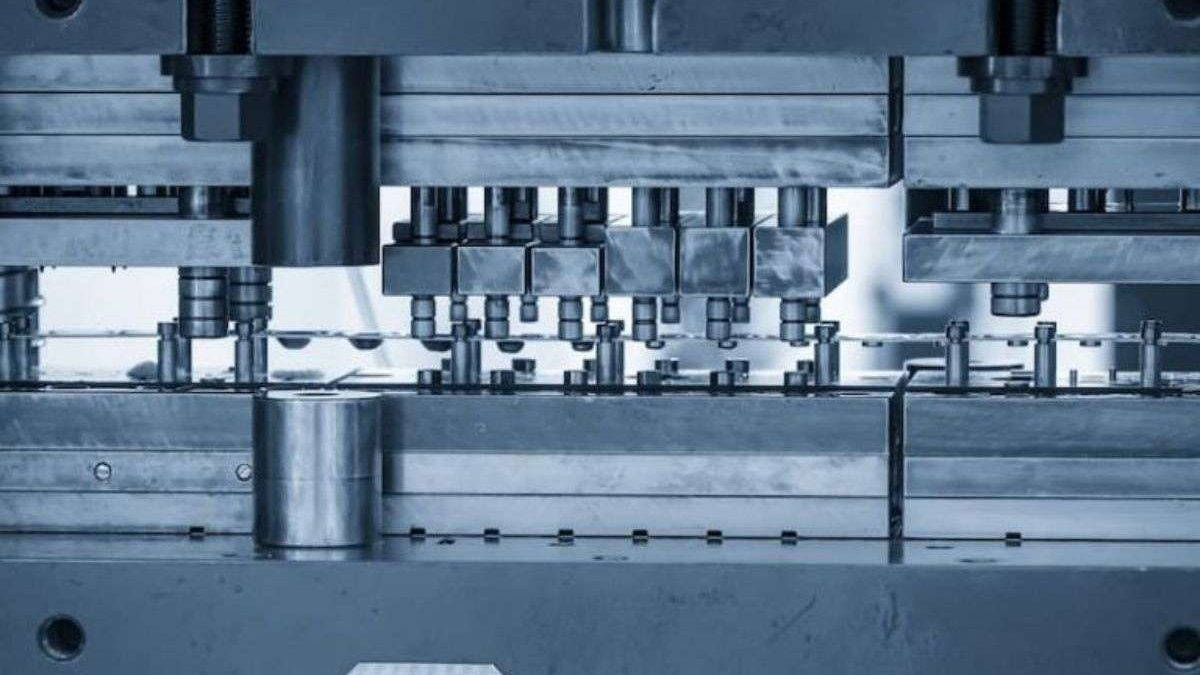

Machinability is among the main characteristics of steel that aids in the selection of the best grade. It is the ability to be cut and cut with a smooth surface. Steel manufacturing companies employ a variety of techniques to produce steel products like steel material bars made of TMT pipes, TMT bars, and steel plates, among others.

To determine the machinability of the steel, take note of the time required by the machine for cutting or incising the specimen steel. This is especially important when it comes to heavy machinery, like reinforced bars and corrugated roofing. Understanding the properties and the performance of steel is vital to ensure the highest output.

5. Resistance to Corrosion

Corrosion resistance is another important element to be considered when selecting the appropriate metal for your job. Steel that is prone to corrosion may be damaged over time, which could affect the strength of the structure. Corrosion can be caused by environmental factors like humidity, moisture, and exposure to chemicals.

Steel material with a stainless coating is a great steel that has excellent corrosion resistance. It has a minimum of 10.5 percent chromium. This creates a thin layer of an oxide of chromium on its surface, thereby protecting against corrosion. This is why it is crucial to take into account the resistance of the steel to corrosion when choosing the most suitable grade for your needs.

6. Weldability

Weldability is the term used to describe a metal’s capacity to create a welded joint without imperfections. It is crucial to take into consideration the steel’s weldability before choosing the best grade for your particular project. Weldability is influenced by a variety of factors, including temperature input, chemical composition, and the cleanliness of the surface.

Steel is among the most frequently utilized metals amaterial cross all industries because of its unparalleled durability, strength, and adaptability. But selecting the best steel for a specific task can be a daunting task. Steel is available in a variety of kinds, and each offers different grades and varying characteristics. It is important to know the various grades and varieties prior to selecting the right steel for your project. We hope that you can use this guide to assist you in choosing the best metal for your task.