Small tools are important in industries where safety and contamination control are issues. A simple piece of tape can end up being a serious issue if it is not noticed and ripped off. This is why metal detectable tape is used in many facilities as opposed to normal tape. It is also intended to decrease the possibility of foreign object contamination and assist the companies in adhering to high safety standards.

Metal tape is widely applied when processing food, pharmaceuticals, and other controlled conditions. It appears just like ordinary tape, except it has special substances that can be detected by the detection systems in case it gets to a production line. In this article, we will explain what metal detectable tape is and how it works.

What is Metal Detectable Tape

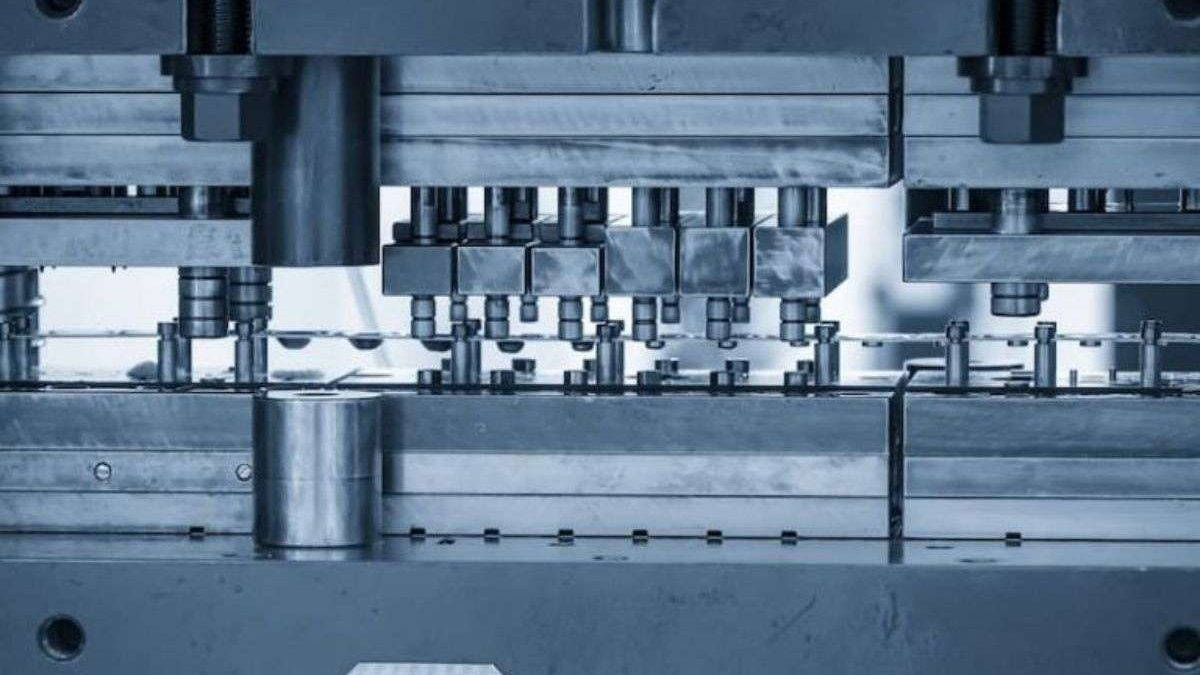

A metal detectable tape is a type of industrial tape that is produced using metal-infused materials. Such materials enable the tape to be identified by the metal detectors and X-ray scanning machines in production premises.

The metal detectable tape can detect alarms unlike regular tape; when it breaks or enters the product, it usually goes unnoticed. This facilitates their easier identification and elimination before they are contaminated.

Types of Metal Tapes

The metal detectable tapes are categorized as:

1. By Material

Foil Tapes: These are often aluminum-backed and provide durability and high detectability. These are used for sealing and general detection.

Metalized Polyester Tapes: These are lighter, often brightly colored like red, blue, and yellow, and are used for visual identification as well as metal detection.

Teflon Tapes: These are known for chemical and heat resistance, with embedded metal for detectability, ideal for food processing.

2. By Application

Single-Sided Tapes: Have adhesive on one side, often used for visual warnings or marking, with printing options.

Double-Sided Tapes: Adhesive on both sides, used for bonding items that need detection, common in food contact.

Underground Warning Tapes: Non-adhesive or adhesive tapes with metallic elements, buried above utilities for future location by locators.

Working of Metal Detectable Tapes

In metal detectable tape, the metal particles are distributed evenly in the matter. Their presence can be detected by a conventional metal detector that is operated in the production lines. As the tape goes through a detector, a signal goes off, warning the staff that the line should be stopped and investigated. This immediate detection enables less time wastage, and spoiled goods are not passed to the next stage.

Small tape parts may cause product recalls, safety breaches, and reputation issues for a company. These tapes provide additional security and assist in avoiding the delivery of contaminated products to consumers.

Applications of Metal Detectable Tape

Metal-detectable tape has many applications in food processing, pharmaceuticals, and other industries that enforce strict safety measures, particularly for equipment labeling or repair, or bundling.

Food Processing: It is used for marking or sealing bags, labeling production lines, securing conveyor belts, and identifying tools.

Pharmaceuticals: It is used for sealing packaging, identifying equipment, and quality control marking.

Medical Devices: It helps to secure components, ensuring no loose tape ends in the final product.

General Manufacturing: It is used for labeling machinery or tools, securing cartons, and general packaging.