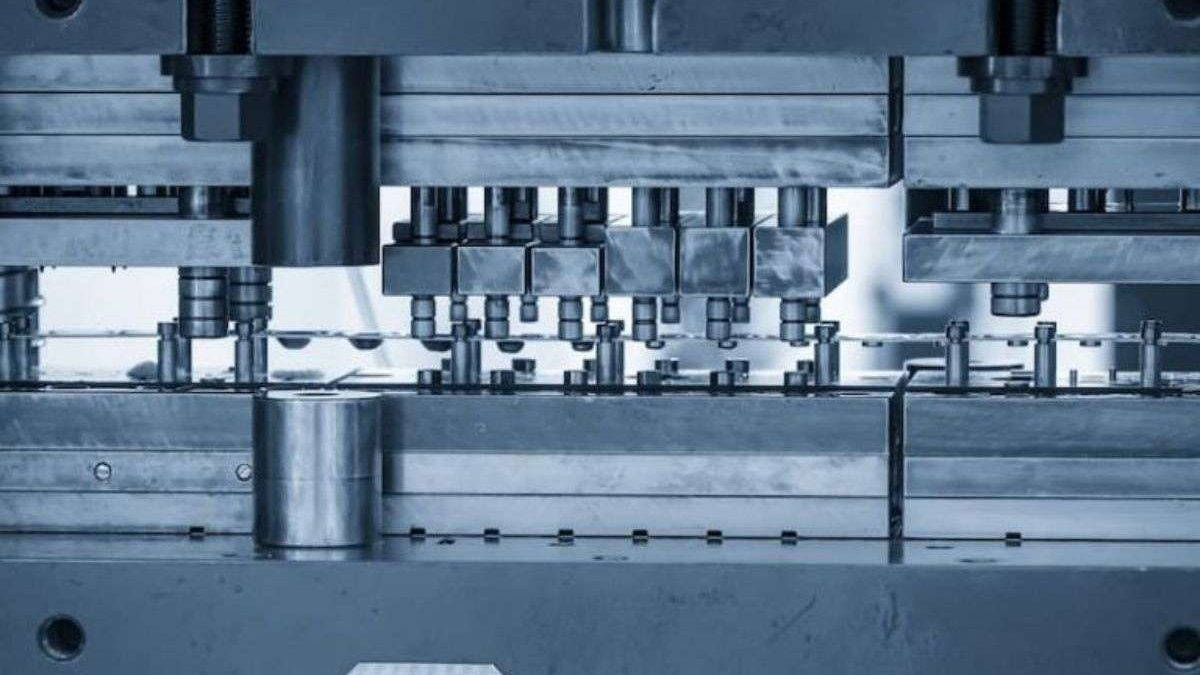

Progressive die metal stamping is a popular method used in manufacturing to create metal parts efficiently and accurately. This process uses a series of dies that shape, cut, and form metal sheets in multiple steps as they move through a machine.

Many industries, including automotive, electronics, and appliances, rely on progressive die stamping because it produces high-quality parts with consistent results. Understanding the advantages of this process helps manufacturers improve productivity, reduce costs, and maintain quality.

High Efficiency and Fast Production

One major advantage of progressive die metal stamping is its efficiency. The process allows a single machine to perform multiple operations at the same time, such as cutting, bending, and forming. This reduces the time needed to make each part and increases the overall production speed.

Companies can produce thousands of metal components in a short period without sacrificing accuracy. Fast production also helps meet tight deadlines and supports large-scale manufacturing projects.

Consistent Quality and Precision

Progressive die stamping provides a high level of consistency and precision in every part produced. The dies are designed to exact specifications, so each piece of metal comes out identical to the others.

This precision is important for industries like automotive and electronics, where even small differences can affect performance. By maintaining consistent quality, manufacturers reduce the risk of defects, improve product reliability, and ensure customer satisfaction.

Cost-Effective Manufacturing

Another significant advantage is cost savings. Although the initial design and setup of progressive dies can be expensive, the long-term benefits outweigh the costs. The process minimizes material waste because it uses the metal sheet efficiently and reduces the need for secondary operations.

Less labor is required because machines perform most of the work automatically. Over time, this results in lower production costs and higher profitability for manufacturers.

Flexibility for Complex Designs

Progressive die stamping can handle complex designs and shapes that might be difficult with other methods. The dies can be customized to perform multiple operations on a single metal strip, allowing intricate patterns, holes, and bends.

This flexibility enables manufacturers to create advanced components for specialized applications. Companies can develop innovative products without compromising efficiency or quality, which gives them a competitive edge in the market.

Durability and Strength of Parts

Parts produced through progressive die stamping are strong and durable. The process creates precise shapes without weakening the metal, which is important for components that must withstand pressure, heat, or regular use.

The high-quality metal parts last longer, reducing the need for replacements and maintenance. Durable components also improve the overall performance of the final product, which is valuable for customers who expect reliability and safety.

Conclusion

Progressive die metal stamping offers several important benefits for manufacturers. It provides fast and efficient production, ensures high-quality and precise parts, reduces costs, allows complex designs, and produces strong, durable components.

This combination of advantages makes progressive die stamping a preferred method in many industries. By using this process, companies can produce reliable metal parts quickly and cost-effectively while maintaining high standards for quality and performance.