Consumer-facing industries, like high-end retail or boutique hospitality, do not want simply utilitarian; their platform trolleys perform double duty as cruising brand ambassadors. Powder-coated frames in Pantone-matched signature colours to fit with store décor; laser-cut logos in side panels change a utilitarian cage to unobtrusive marketing merchandise. Bumpers and deck graphics in corporate palettes are also being ordered by industrial sites, furthering brand recognition for clients and, say, investors touring the plant floor. Textile manufacturers swathe trolley handles in washable faux-leather sleeves embossed with the company crest so that the gear slips, sneaky, into the social-media-ready behind-the-scenes picture with none of the hygiene risk. Aesthetic thoughtfulness brings more to the table than good looks – it breeds employee pride of ownership, which minimizes vandalism and “shadow fleet” hoarding that grey, uninspired products tend to encourage.

Neuro-Wearables and Biometric Feedbacks

The new platform trolley is now also connected to ergonomically operating close-circle systems. Workers wear soft exoskeleton belts or wrist-worn electromyography devices that send data on muscle strain to cloud dashboards.

If a labourer’s effort spikes into the danger zone, the platform trolley’s LED pulse amber – a nudge for the operator to slow pace down or re-distribute the load. By crunching the combined biometrics, fleet managers can every week, not once a year in injury audits, tweak caster diameter, tyre compound and handle geometry. A future, in which it is real-time biofeedback, and not static design guidelines, pushing this-this-and-that micromanagement of your manual-handling techniques to reduce and reduce compensable claims (even as lean machines churn out more throughput than the system can accept).

Evaluation of suppliers beyond the quotation sheet

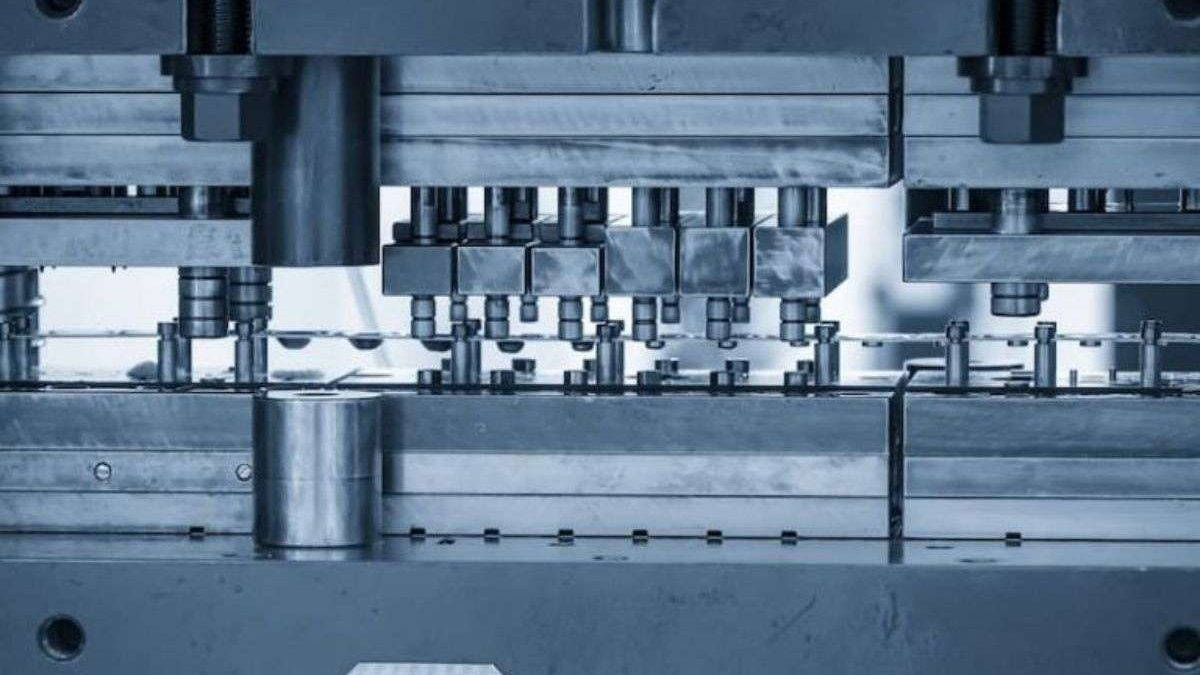

Price-per-unit and lead time are still gatekeeper metrics, but forward-leaning buyers are now stripping away deeper layers: Is the supplier running random batch ultrasonic weld inspections? Do they have third-party life-cycle analyses for their products including Scope 1, 2 and 3 emissions? Is their quality management system ISO 9001:2015 registered or has moved to the risk-based ISO 9001:2025 draft? Just as important, in the end, is post-sale responsiveness — a supplier with a regional parts depot and 24-hour tech-support hotline can help you avoid a significant amount of down time when the axle snaps the night before Black Friday. Site visits also reveal the intangibles of culture: neat and tidy work-cells, clean weld booths – or, oppositely, dishevelled jig fixtures that indicate a foretelling of dimension creep down the line. Moreover, by “scoring in” such qualitative indicators with unit cost, organization shifts more towards transactional sourcing to strategic supply relationships that can withstand demand shocks and regulatory changes.

Why is it Important?

Before a single trolley has rolled off the production line, its digital twin can already be manoeuvred through a customer’s CAD-rendered warehouse. Engineers feed deck dimensions, caster swivel offsets, predicted weight distribution into discrete-event simulation software to assess pinch-points, ramp inclines, lift-door clearances. Virtual commissioning shaves physical prototyping iterations, thus reducing project-to-floor time and catching catastrophic miss-fits— say a door-handle fouling the emergency-exit crash bar—well before metal hits the laser cutter. And after they’re in operation, sensor-equipped units send telemetry back to the twins, closing the loop with real-wear data that recalibrates friction coefficients and caster alignment models, tweaking future fleet specs. Digital-twin approach moves procurement game from guesswork to science.

Ethics of Data Ownership in Smart Fleets

Trolleys record load weight, travel paths and user IDs, which raises questions of ownership — the employer, the equipment vendor, or the third-party analytics firm hired to do the work? Well considered contracts now contain data-sovereignty clauses aligning with GDPR, which restrictions how vendors may monetise anonymised aggregates. Unions are calling for more transparency about wearable-linked ergonomics metrics, concerned that surveillance tools designed to prevent injury might turn into productivity policing. By setting up cross-disciplinary data-governance manufacturers like equip2go that include both management, IT security and front-line staff, such policies can develop democratically, balancing innovation against privacy rights and trust, building confidence that analytics serve safety first.